เมนูเว็บ

การค้นหาผลิตภัณฑ์

ภาษา

ออกจากเมนู

ท่อทองแดงเป็นบริการ: เมื่อการผลิตแบบดั้งเดิมเป็นไปตามเศรษฐกิจแบบสมัครสมาชิก นวัตกรรมรูปแบบธุรกิจจะปรับเปลี่ยนภูมิทัศน์ตลาดมูลค่าแสนล้านดอลลาร์อย่างไร

Subtitle: Germany's Wieland Group launches a "pay-per-flow" smart copper tube solution, and Japan's Mitsubishi Materials rolls out a predictive maintenance subscription service—can this shift from selling products to selling services solve the industry's persistent profit decline?

Business Model Transformation: From "One-Time Transactions" to "Continuous Value Creation"

In 2025, the copper tube industry is undergoing a profound business model restructuring. The traditional "produce-sell" model faces severe challenges: the industry's average profit margin has fallen to 3%-5%, while accounts receivable cycles have extended to over 92 days . Against this backdrop, the "Tubes-as-a-Service" (TaaS) model has emerged. Leading companies are leveraging IoT and big data technologies to transform one-time transactions into continuous service relationships.

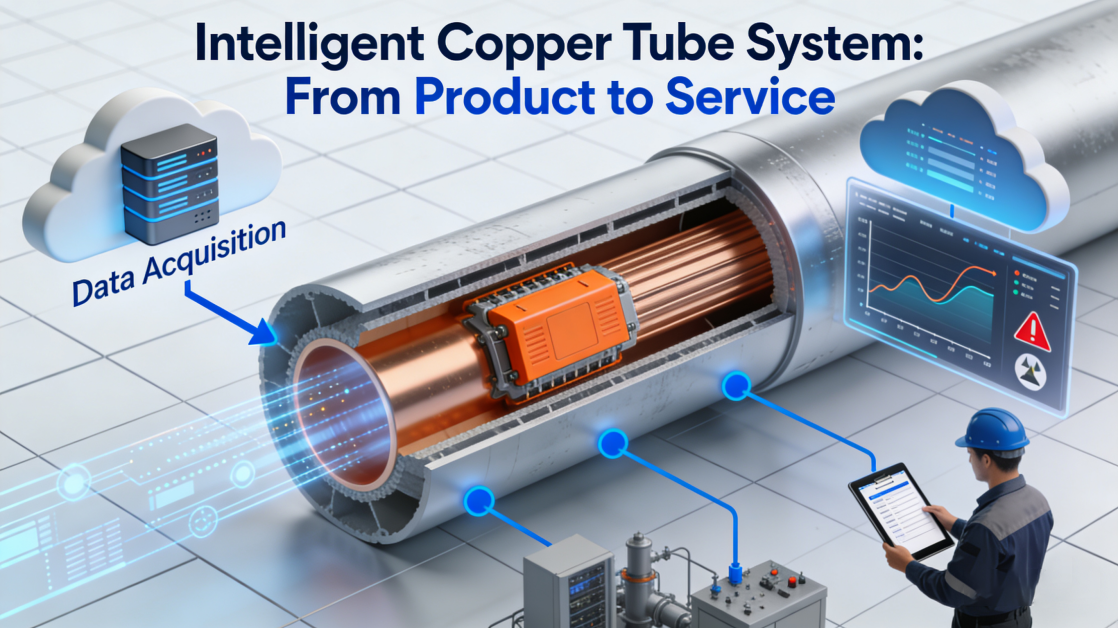

Germany's Wieland Group's " Smart Copper Tube System " is a prime example. This solution embeds sensors within copper tubes to monitor flow, temperature, and pressure data in real-time, with customers paying based on actual usage. This model has increased the company's gross margin from 6% for traditional products to 28% for the service model. More importantly, it creates a steady cash flow—contract renewal rates for signed customers are as high as 92%.

Japan's Mitsubishi Materials focuses on predictive maintenance services. Its subscription packages include remote monitoring , fault early warnings , and regular maintenance , reducing customer repair costs by 40% and equipment downtime by 60% . This transformation not only enhances customer loyalty but also fundamentally changes the company's valuation logic: the higher the proportion of service revenue, the greater the price-to-earnings ratio premium awarded by the capital markets.

Table: Key Indicator Comparison: Traditional Sales Model vs. Servitization Model (2025)

| Evaluation Dimension | Traditional Sales Model | Servitization Model | Improvement Magnitude |

| Gross Margin | 3%-5% | 25%-28% | 8x improvement |

| Customer Renewal Rate | Primarily one-time transactions | 92% | Guaranteed recurring revenue |

| Valuation Premium (P/E Ratio) | 8-10x | 15-18x | 80% improvement |

| R&D Investment Ratio | 1.2% | 4.5% | 3.75x growth |

(This image was generated by AI.)

Technological Foundation: How IoT and Big Data Enable Servitization

The servitization model is underpinned by substantial technological accumulation. The cost of embedded sensors has dropped by 67% over the past three years, making large-scale deployment feasible . Current smart copper tubes can monitor 12 parameters, including vibration frequency, corrosion rate, and wall thickness variation, with a data acquisition frequency of 1,000 times per second.

Data value mining is even more critical. Using machine learning algorithms, companies can predict the remaining lifespan of copper tubes with 96% accuracy . A European chemical company that adopted predictive maintenance services reduced its unplanned downtime from 86 hours per year to 14 hours, avoiding approximately $2.7 million in production losses annually.

Digital twin technology further amplifies the service value. Manufacturers build virtual copper tube systems for each client, running over 100,000 simulation tests before implementing new formulas or adjusting parameters. This "test-before-buy" model significantly reduces customer decision-making risk, increasing the deal closure rate by 34%.

Regional Practices: Divergent Global Layouts and Path Selection

Servitization transformation shows distinct regional characteristics. European companies primarily offer high-end service packages, such as KME's "Zero-Leakage Guarantee Plan," which combines blockchain technology for full lifecycle carbon footprint tracking. North American companies focus on cost savings; Mueller Industries introduced an "energy efficiency sharing model" where customers incur no upfront costs and share in the saved electricity expenses.

The Asian market exhibits leapfrog development. China's Hailiang Co., Ltd. launched a "Cold Storage as a Service" package in Southeast Asia, bundling copper tubes with refrigeration systems and charging based on refrigerated volume . This model is particularly suitable for small and medium-sized cold chain enterprises, allowing them to access advanced technology with zero initial investment.

Financial Restructuring: From "Asset Burden" to "Value Lever"

The servitization model has completely altered the industry's financial structure. Under the traditional model, low capacity utilization (averaging 65%) caused significant resource waste. The servitization model improves asset efficiency through sharing mechanisms: one smart copper tube system can serve multiple customers simultaneously, increasing equipment utilization to over 85%.

More importantly, it improves cash flow. In the traditional model, companies bore high raw material costs (with volatile copper prices) and long payment cycles. Under the servitization model, customers pay monthly fees, providing companies with stable cash flow and reducing financing costs by 30%.

The capital market has clearly endorsed this change. Companies with service revenue exceeding 40% receive significantly higher valuations than traditional manufacturing companies. A Zhejiang copper tube company's stock price rose 57% within three months after launching its "Smart Water Steward" service, far exceeding the industry average increase.

Future Trends: Ecosystem Competition and Standardization Game

Servitization competition is evolving from "single-point breakthroughs" to "ecosystem co-construction". Leading companies are attracting third-party developers to create value-added applications through open API platforms. Similar to smartphone "app stores," copper tube companies charge a 30% commission, building a cross-border innovation ecosystem.

Standardization is becoming the next battlefield. The EU is formulating data interface standards for smart copper tubes to promote device interoperability. Companies that master standard-setting are expected to dominate the next generation of competition.

AI agents will further enhance service value. Systems will automatically optimize energy consumption, provide early fault warnings, and even autonomously order replacement parts . Within five years, fully autonomous smart copper tube systems are expected to reduce the need for human intervention by over 80%, truly achieving "unmanned" operation and maintenance.

Challenges and Risks: The Hidden Costs of Servitization Transformation

The transformation is not without risks. Data security is a primary concern, with industrial systems experiencing a 120% yearly increase in cyber attacks. If sensor data is tampered with, it could lead to systemic misjudgments.

Customer acceptance is also a key challenge. Traditional manufacturing enterprises are accustomed to owning assets rather than subscribing to services. Changing this mindset takes time. Surveys show that 43% of customers still worry that long-term service costs may exceed one-time purchase costs .

The talent structure urgently needs adjustment. The servitization model requires interdisciplinary talent skilled in industrial technology, data analysis, and customer service. Such talent is scarce, and salary costs are 35% higher than for traditional engineers.

Servitization is Not a Choice, But an Inevitability

The servitization transformation of the copper tube industry has surpassed the scope of technological upgrading, becoming a reconstruction of the business model itself . When Wieland Germany boosts its gross margin to 28% through smart services, and Hailiang China achieves "payment by refrigerated volume" in Southeast Asia, traditional price wars lose their meaning.

Over the next five years, enterprises that fail to transition to servitization will face a dual squeeze: the high-end market will be captured by digital service providers , and the low-end market will sink into more brutal price wars . Only by upgrading core capabilities from "producing high-quality copper tubes" to "providing reliable fluid solutions" can companies secure a place in this unprecedented century-old transformation.

ข่าวที่เกี่ยวข้อง

-

หลอดทองแดงที่มีผนังหนาคืออะไร? หลอดทองแดงที่มีผนังหนาหรือที่รู้จักกันในชื่อท่อทองแดงที่มีผนังหนาไร้รอยต่อเป็นท่อโล...

See Details -

ภาพรวมและความสำคัญของหลอดเส้นเลือดฝอยทองแดง ในอุปกรณ์อุตสาหกรรมที่ทันสมัยและระบบควบคุมความแม่นยำขนาดเล็กและความแม่...

See Details -

หลอดทองแดงคืออะไร? การวิเคราะห์องค์ประกอบของวัสดุและลักษณะพื้นฐาน คำจำกัดความของหลอดทองแดง หลอดทองแดงเป็นวัตถุท...

See Details -

การทำความเข้าใจกับท่อสี่เหลี่ยมทองแดง: องค์ประกอบเกรดและแอปพลิเคชันทั่วไป ท่อสี่เหลี่ยมทองแดง เป็นการอัดขึ้น...

See Details

![]() Tangpu Industrial Zone, Shangyu District, Shaoxing City, Zhejiang Province, China

Tangpu Industrial Zone, Shangyu District, Shaoxing City, Zhejiang Province, China

![]() +86-13567501345

+86-13567501345